Mini- Desktop- professioneller Hersteller von CNC-Fräsermaschine

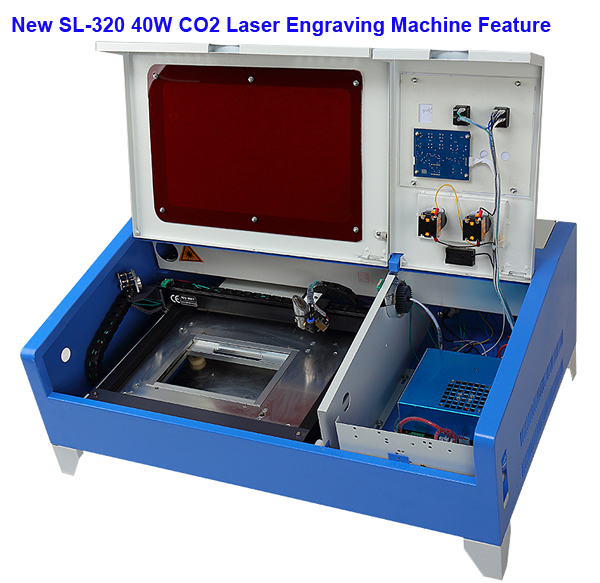

Compared with older version JK-3020 DIY CNC Laser Engraver, our SL-320 40W CO2 Laser Engraving Cutting Machine has below advantages:

1. New Power Supply

Built-in cooling fan in the power supply of new version, it extends power supply’s life to 150%.

2. New Main Board

New main broad solved the static burning problem in old one.

As for speed, now max engraving speed reach 600mm/s, old one just 400mm/s.

3. New Laser Tube

The using life of new laser tube is 1000-1500 hours, old one just is 800-1000 hours.

Remove sponge before use

4. New Controlling Panel

A. Water temperature sensor added, it monitors water temperature real-time.

( PS: When water temperature beyond 50℃, just need replace half water

in tank. Laser tube may broke if replace all circulating water into cold

water one time.)

B. Emergency stop switch added, machine’s security increase.

C. Power supply key added, avoiding others use machine in wrong way.

D. LED light on-off key added, energy-efficient .

E. Power on-off key added.

5. New Guide Rail

X axis has upgraded to square rail from aluminum rail.

Y axis has upgraded to round rail.

Its stability increase.

6. New LED Light

The light has upgrade fluorescent lamp to LED light, longer using life.

7. New Limited Switch Added

New version machine use 2 high quality mechanical limit switches in X/Y axis,

and 1 limited switch for open-close protection function.

machine’s security increase.

8. Platform Height Adjustable

Platform height adjust by manual, max height is 5cm.

9. 3 Reflectors and 1 Focus Lens

High quality reflector and focus lens ensure the laser source 100% conserve to the laser head.

10. Air Assist and Red dot Point

Air assist for blowing flame retardant, 18W air pump, flow can be 38L/Min.

Red-light point for help choosing the starting point quickly.

11. Ground Lead Wire and Air Exhaust Fan

Please connect ground lead to ensure machine work in safe condition.

Air exhaust fan can help air circulation and exhaust gas and odor.